WARNING

WARNING  this will void any warranty you may have whether or not it works. It involves fire and heating up electronics , so it may in fact damage your screen and make things worse . Be careful, don’t burn yourself, and also don’t burn down your house, street, neighbourhood, town, region, country, continent or planet, please. Keep a window open so that there’s good airflow and you don’t inhale anything that’s bad for you.

this will void any warranty you may have whether or not it works. It involves fire and heating up electronics , so it may in fact damage your screen and make things worse . Be careful, don’t burn yourself, and also don’t burn down your house, street, neighbourhood, town, region, country, continent or planet, please. Keep a window open so that there’s good airflow and you don’t inhale anything that’s bad for you.

If you’re uncomfortable with the procedure described below, or if you’re a kid, either just don’t do it or get someone who knows about safety to help you . Only do this if you have another screen at the ready, because there’s a chance this one will get overheated and stop working . This procedure does not come recommended by anyone, even by me, but it did work on both occasions that I’ve used it.

Read at your own risk! Please turn off your computer now and never turn it back on! Step away from the forum with your hands where I can see them!

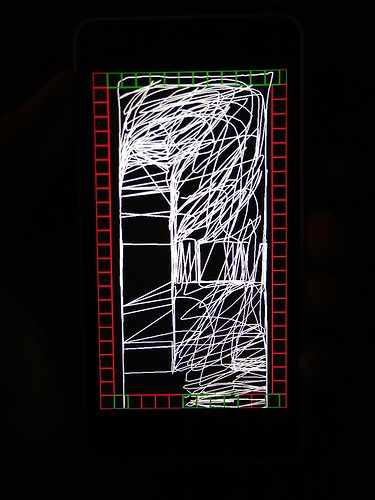

I had two partially unresponsive FP2 screen modules laying around in my box of spare parts, and I figured some experimentation wouldn’t hurt. May as well try to fix them before recycling them, after all. One had a 1 cm wide vertical band that didn’t respond to touch, and the other had three such bands.

Now, when we were kids we used to fix Game Boy screens with malfunctioning pixel columns by leaving them in the back of a car to heat up in the sun, or by holding them over a hot stove. The heat loosens up the various binding agents, allowing contacts to resettle and make contact where they didn’t before. So the pixel columns came back, and as Fairphones are essentially just more expensive Game Boys, why not do the same?

So I took a screen module, and held it (with a hefty oven mitt) above one of the burning gas jets of my stove, at a height of about 40-50 cm. I kept it moving so as not to overheat any one area of the module. I held it screen side down for about a minute and a half, after which I switched to screen side up, more briefly this time. Be careful with that last bit, as the plastic parts can melt if they get too hot. When the screen module was heated through and too hot to touch, I laid it down flat, screen side down (on a heat-resistant, non-scratching surface!). While it cooled, I placed a folded up tea towel on it and pressed down on it with my palms. I don’t know if that last bit did anything, but I did it anyway.

After letting the module cool all the way down to room temperature, I attached it to the phone and bam, there it was. 100% responsive, good as new.

I have now done this to both of my defective screen modules, and they still work 100% flawlessly after three days. One has been in use in my test bench FP2, the other one has been stored away and I successfully tested it just now. This procedure probably hasn’t done the longevity of these screens any favours, but they can now be used as spare parts in a pinch - when someone’s waiting for a new replacement or can’t pay for a new module.

. I have an issue with an FP1 screen and it sounds similar.

. I have an issue with an FP1 screen and it sounds similar.