On the “why” of the battery screws … (this might have been explained before elsewhere)

What I was told at the Launch event by Fairphone was that based on “customer data”, customers found the recent Fairphone models bulky and heavy. So one of Fairphone’s targets in designing the FP6 was to make it smaller, flatter, lighter. This has been achieved (see Fairphone dimensions and weights). However, this resulted in the need for battery screws. Perhaps a closer look at the battery helps to explain this.

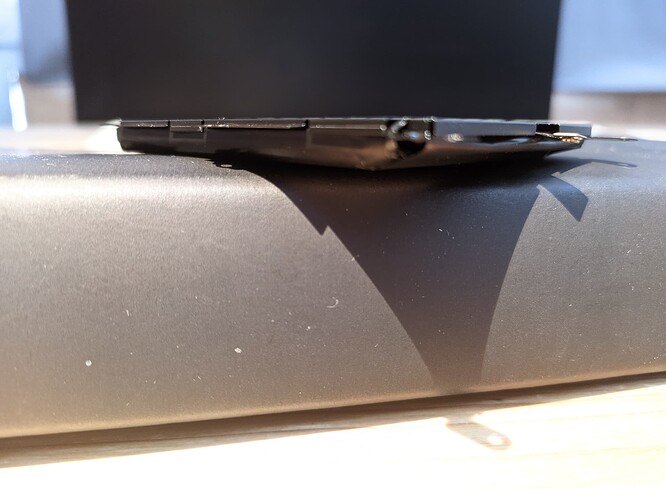

The photos aren’t perfect, but what you can probably spot is that the downside of the battery (visibile in photos 2 and 3, silver grey label) and the upside (all black and with lime colour fairphone logo, not fully visible in the photos) are not symmetrical. And the upside is enforced with a hard plate that almost feels like metal. The downside is not hard-cased (to allow for an overall flatter device).

Now the screws serve to ensure that the battery sits tight and does not move.

My own concern with this is a different one. My FP3 experienced a dive in August 2023, it was fully submerged in water. Thanks to easy access to the battery, I could remove the battery within seconds. I disassembled the whole device to the max afterwards, rinsed the unsensitive parts and gave it 72 hours to dry. The FP3 remains my daily driver until today and shows no sign of aging (although the liquid ingress sensors are both red, probably from the dive).

P.S.: Useful to know: As in the FP4 and FP5, hardware tests can be found

by dialling * # * # 2 8 8 6 # * # *

(I was a bit nervous if I had succeeded in pressing the battery press connector correctly into place again ![]() )

)