Originally published at: https://www.fairphone.com/en/2021/03/04/our-north-star-the-material-roadmap/

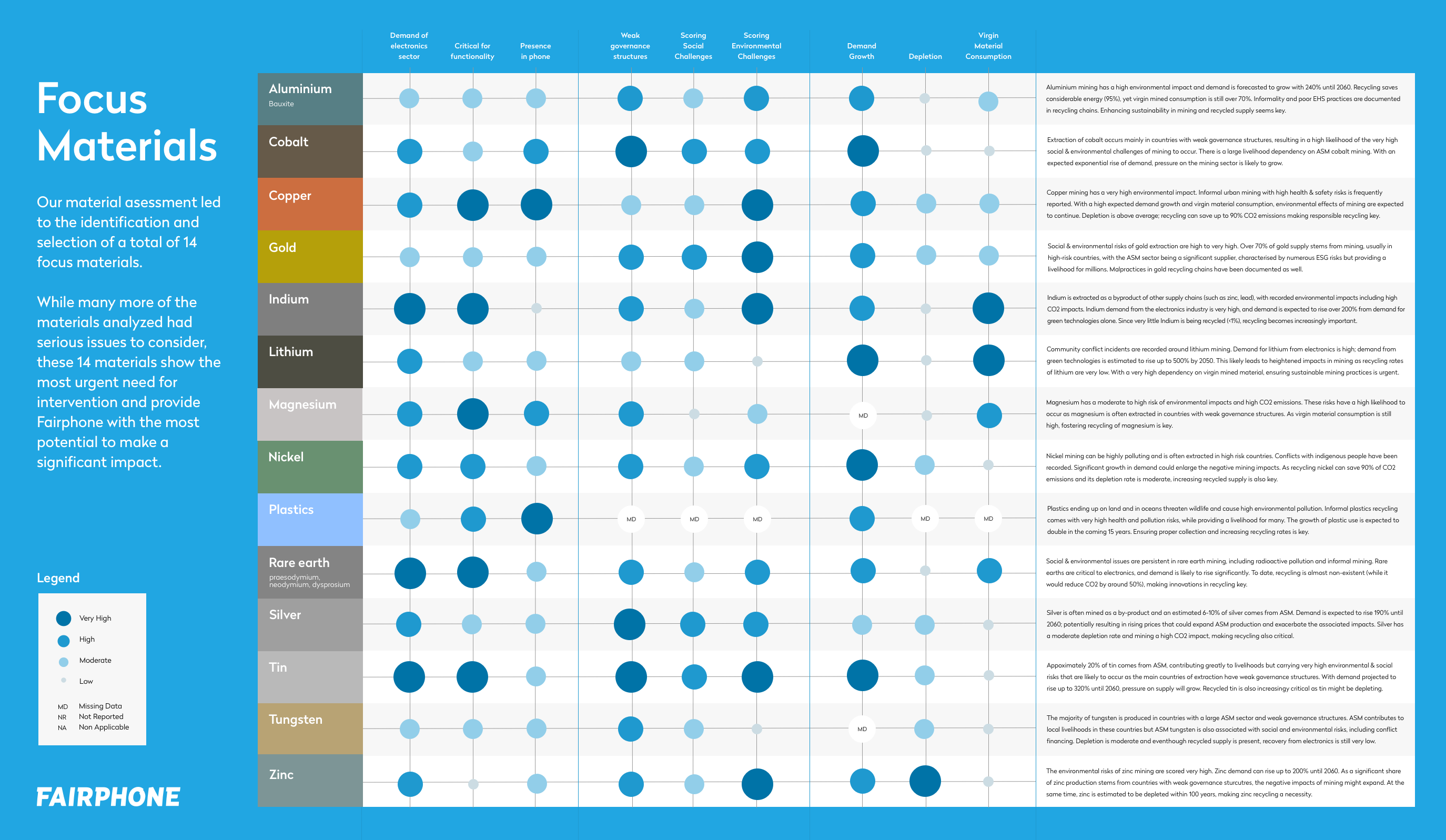

At Fairphone, we continuously strive for a transparent product. We tell you everything we know about what goes into your phone, but we also know there is more to know. We collected full materials declaration on more than 90% of the components used in our phone, and through a thorough assessment and evaluation of a long list of materials, we narrowed our Fair Material Sourcing efforts to 14 selected materials – the ones with the most potential for supply chain improvement.

What does this mean for you? It means you are able to make an informed decision and know that you are contributing to a fair and circular economy. As you probably already know, where and how we source the materials we use in our phones is very important for us. So important that we wrote a paper about it.

Key challenges & opportunities

The use of electronics has exploded in recent years and with that comes an increase in materials use, as well as an abundance of e-waste, which has been defined as the worlds’ fastest growing waste stream. The electronics sector is in a position to address and catalyze social and environmental improvements throughout material chains, including in mining and recycling.

The materials and minerals that the electronics industry relies upon to make many of the products we use daily, are vital in ensuring those products work. Many of those minerals come from unsustainable sources – both in mining and recycling – that threaten the health and safety of those who work in that industry or live, work, or play in the surrounding areas. Therefore, we and the wider electronic industry have a responsibility to make sure the materials used are sourced fairly – where (urban) miners are working safely, children are not being exploited and communities are benefitting.

What we are focussing on

At Fairphone, it starts with our long term vision of a world in which we are truly circular – materials can be used, reused and recycled to their full extent and we would not need to mine new materials to meet our material demand. But it is not that simple and the mining sector will remain a key supplier for years to come. Even if electronics were 100% collected for recycling -which they aren’t, it’s rather 17% – due to the complexity of production and recycling, many of the materials needed for smartphones can’t come from recycling alone. As the demand for more products increases, so does the need for raw materials. However, where there are challenges, there also lie opportunities. As a result, we have decided to focus our efforts on positively transforming both the recycling and mining sectors.

The approach

Smartphones contain dozens of different elements and materials, each with a different supply chain stemming from mined and/or recycled sources. Our supply chain includes mines, smelters, refiners and multiple tiers of manufacturers that span the entire globe. Many in the industry would tell us we have our eyes set on an impossible task, but step by step we are mapping out our supply chain to understand exactly what goes into our phones, where everything comes from, and in which supply chains we can make a positive impact.

To determine which material chain we believe we can influence, as Fairphone and the electronics industry at large, we developed a methodology in order to analyze opportunities and challenges in the different supply chains. We analyzed whether the material is present in our products, what share of demand can be attributed to the electronics industry for each material, the criticality in the functioning of our phones and the key social and environmental issues for these materials. From there, we determined which supply chain is reachable and the most critical to address.

To download the full matrix click here.

Results

We see an opportunity for the industry to drive the changes needed in both the recycling sector and mining industry. Through our Fair Material Sourcing Roadmap, we have identified critical ways forward:

- Developing scalable post-consumer recycling chains, which needs to be pushed and demanded for by the electronic industry – only a small share of the products that reach the end of life are effectively recycled. Some of the e-waste ends up in the informal recycling chain – often in a developing country that lacks infrastructure, risking the health and safety of people working in this sector; and

- Transforming the mining industry, specifically the artisanal and small scale mining sector (ASM), which often uses elementary forms of exploration, material extraction, processing and transportation – generally, an unskilled labor force using very basic tools and techniques. Opportunities lie in positively impacting the many people dependent on this sector for their livelihood and not ignore it any longer.

Fairphone is in a unique position to (co)develop new approaches to tackle systemic issues in the mining or recycling sector, following our fair sourcing principles. The road ahead is long, but we are heading in the right direction with the help of our roadmap, yet we can’t do this alone. To really transform the industry, many actors need to be involved and work together. We are open to feedback and welcome partnerships in order to tackle these topics and drive the change that is necessary.